Motorcycle Investor mag

Subscribe to our free email news

Our bikes – 1998 Ducati 916

August 2020

Clutching at Ducs

by Guy 'Guido' Allen; pics by Ben Galli Photography

Getting into the giblets of the 916

Not sure how this happened, but it was rolling over five years since Nina the 916 managed to find its way into the shed. Frankly, it seems like yesterday that I wandered in to the Peter Stevens emporium in Elizabeth Street and plonked down the modest deposit in anticipation of a tax refund covering the rest.

I had in fact been stalking the bike for some months. A 1998 Japanese import (buggered if I know why people get precious over whether it’s delivered here or elsewhere, so long as it’s a full-power model), it was on the market for $13,500.

Even at that price I was tempted. But as I wandered out of a Melbourne coffee shop one morning – ironically with Vince Chiodo (RIP), one of the owners of the business – I saw it loaded on a truck and heading off. Well, missed that one, I thought.

At the time, 916s were pretty much top of my shopping list. They’re Massimo Tamburini’s most famous design (closely followed by the MV Agusta F4), were the basis of numerous world superbike titles and prices had fallen into the low teens. This for a machine that started out around the $17-20k mark in the mid to late 1990s.

I didn’t think they’d drop any further and would at some stage start going up again – so it seemed like the time to buy, an opinion shared by resident Ducatisti and historian Ian Falloon.

Months passed, I was casting my net across the web and the same damn bike popped up, back in Elizabeth Street and now priced closer to $12,000. That was it – I marched in Saturday afternoon and did the deal.

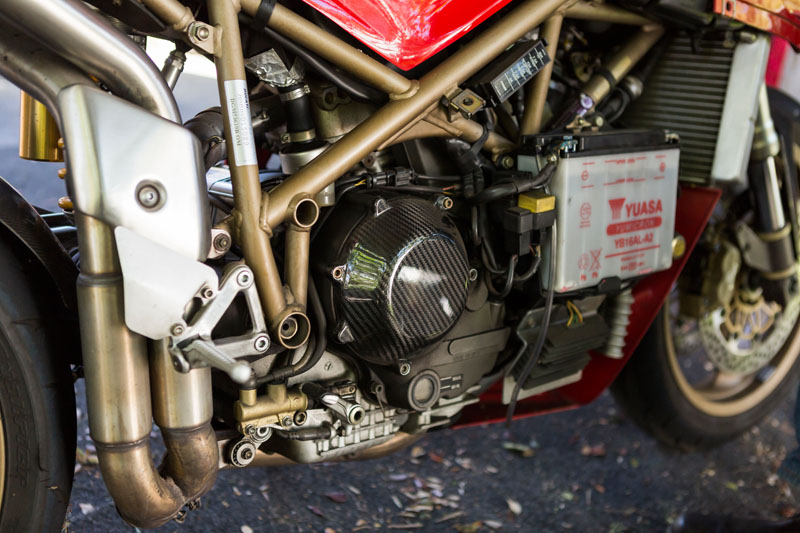

The shop had serviced it and thrown on a new set of rubber and, with 30,000km on the clock, it was crisp. Perfect, really. It’s a Strada – the base model – and a previous owner had dressed it up as an SP. I decided to finish the job with a little carbon fibre trim (front guard, rear hugger and chain guard) and an Ohlins rear shock, bought second-hand and rebuilt.

It’s only done a few thousand kay since. Really, it’s an occasional Sunday toy and I get almost as much pleasure out of viewing it over a glass of wine as riding it. It may have hit over 25 years old, but it’s still a looker.

Values haven’t moved much since it joined the fleet, which is fine. If, in the end, you get most of your money back and have had some fun, that’s a great result.

However, used or not, old bikes need care and seem to have a talent for emptying your wallet even when they’re not moving. For example, Ducatis with belt drive heads need those cam belts changed every two years (or up to five if you use the right updated parts) regardless of whether they’re being used. The mileage limit is 20,000km.

It costs several hundred dollars and is something you don’t let go, not if you value your engine. So I’m up for my second set soon. There’s no use whinging, as I knew going in this was part of the whole ownership experience. You don’t buy a pet and then complain about having to worm it.

Latest on the list was the clutch and I’ll admit to being spectacularly slack about this. It had been slipping for a while and I had been riding around the problem. But what finally drove me into action was the rattle, typical of dry clutch Ducatis, had become a cacophony. Think a couple of chainsaws let loose in a 44 gallon drum.

These multi-plate clutches look like a conventional motorcycle unit, but they’re not running in an oil bath, and there is room for the plates to rattle around in the basket – hence the noise. Over time the plates and basket can wear, increasing the noise.

Finding replacements was no problem, the issue was working out which of a herd of options was the one to use. There are plenty, including ones that give you an open cover, different master and slave cylinders (it’s an hydraulic-operated unit) and various dress-up bits. Dress-up bits for a clutch?! Yep, it’s possible.

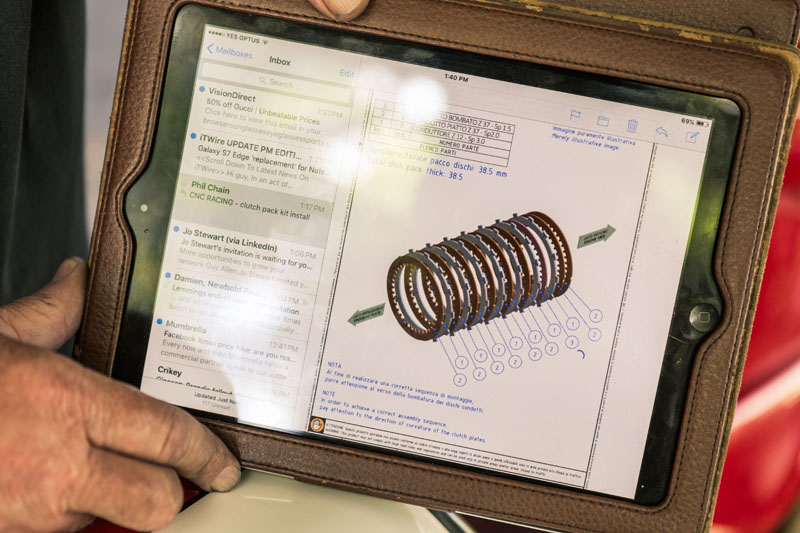

What I ended up going with was a CNC Racing unit coded KD016. It’s their middle-ranked unit, one up from the standard street kit and one back from a full race kit. The reason was it was made of better materials than the stocker and should last better. That set me back about $650 from sportsbike.com.au. It included a hub-holding tool (a small alloy toothed item that bolts to the outer edge of the clutch casing), to stop the clutch rotating as you undo the centre nut. You will not be able to do the job without one.

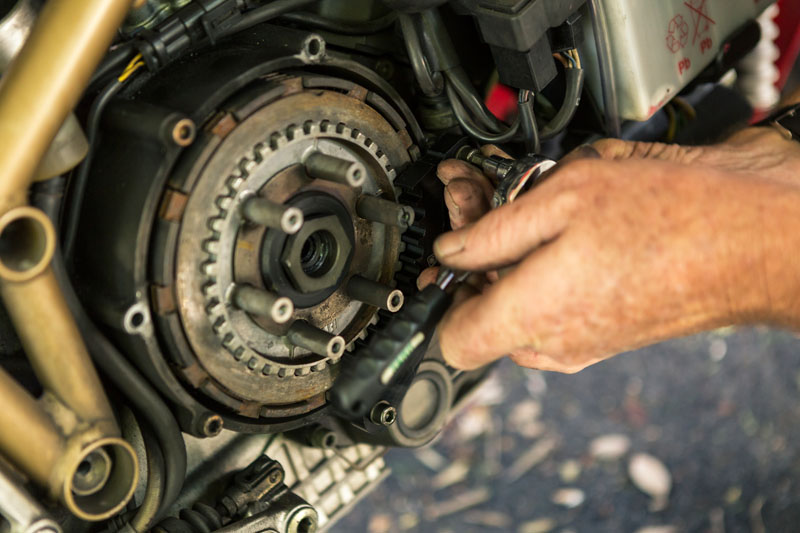

It’s debatable, but maybe I should have replaced the clutch basket at the same time, which would have more or less doubled the expense. They do wear, though mine looked fine for the time being.

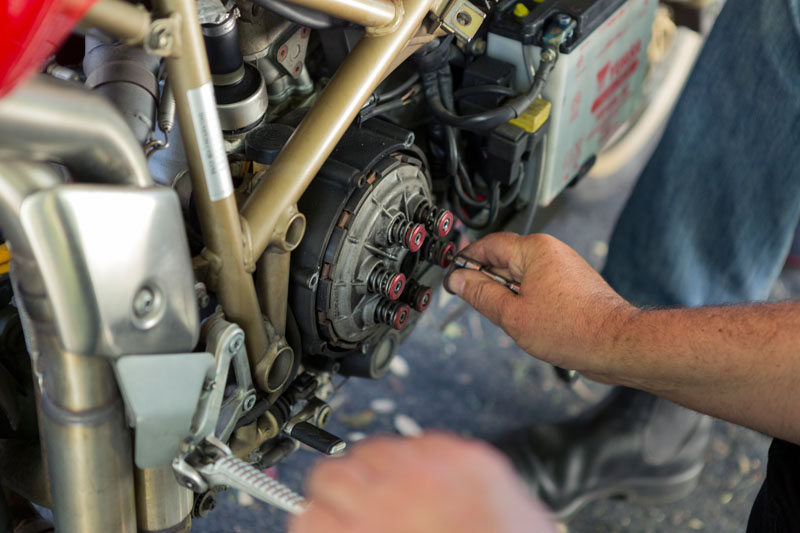

For this sort of relatively simple job, these Ducatis are pretty good to work on. The fairing panel comes off in a couple of minutes with just a few Dzus fasteners. Fantastic. Once you’ve popped off the clutch cover, it’s a matter of undoing the springs and the pressure plate, which is the gizmo with the long shaft attached. So far so good.

The real challenge is undoing the centre nut, which is installed at a pretty substantial torque. We ended up resorting to an impact driver to ‘shock’ the thing loose, before using an ultra long wrench for leverage. And yes, we did double-check that we were turning it the right way! Having worked on some quirky motorcycles recently, I was painfully aware of the possibility this used a left-hand thread. It doesn’t and it’s perfectly conventional.

Next issue was how the hell do we reassemble it? Close examination of the plates revealed they weren’t all identical and there was a slight curvature on some of them. That’s when I got on the blower to Phil at Sportsbikes and he emailed through an assembly diagram. Which raises one of my favourite workshop tools: an iPad. I use it surprisingly often for assembly guides, wiring diagrams and the like.

Once we had that nutted out, putting the whole lot back together was very straight forward. The final twist was there is a specific tension the hub nut has to be wound up to, so a torque wrench is essential.

Speaking of tools, I also had my workshop buddy – Paul Newbold of the SR500 club - with me. I’ve discovered in recent years that one of these is very handy. They stop you getting cranky and throwing the bike over the back fence, and it’s good to have someone experienced to help out and bounce ideas off.

Somehow I ended up with two of them – workshop buddies that is, not Newbolds. It turns out ace photographer Ben Galli (that's him in the pic at top) enjoys getting up to his elbows in bike internals and we sometimes found ourselves in the odd situation where I was holding the camera and he was on the tools. Whatever works…

In the end, we ticked off the three markers of a job done properly: There were no tools missing; There were no parts left over; And the motorcycle works!

See more at the Our Bikes page

-------------------------------------------------

Produced by AllMoto abn 61 400 694 722

Privacy: we do not collect cookies or any other data.

Archives

Contact