Motorcycle Investor mag

Subscribe to our free email news

MotoCAP open day

A look behind the scenes at the

riding gear testing centre

The

MotoCAP motorcycle safety gear testing site

at Deakin University in Geelong today held an open

house in partnership with the launch for Motorcycle

Awareness Month in Victoria, Australia. Its

modest facility evaluates a range of clothing and is

notable for developing a lot of expertise in assessing

jackets, pants and gloves. Here is our quick overview.

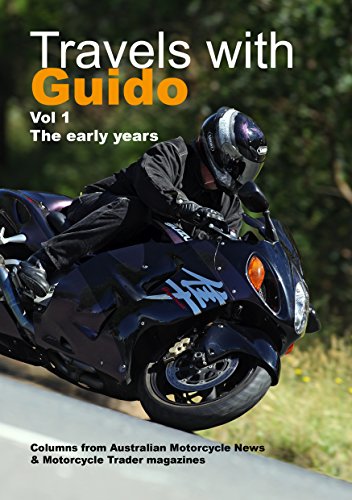

(Guy 'Guido' Allen, October 5, 2024; top pic by

MotoCAP)

Behind the public website is a crew which buys

duplicate motorcycle gear from retailers, both from

brick-and-mortar shops and online. The idea is to

ensure the samples are random.

From there it's assessed for 'live-ability' with the

assistance of experienced riders. Those issues include

does it bend and conform when you sit on the bike, are

fasteners accessible, does it generally do what you

might expect on first meeting.

And here's a little detail: does it have metal parts

(rivets/fasteners) that are on the outer shell and go

through to touch your skin? If so, that's seen as a

potential heat-transfer point that could burn you

through friction.

The clothing is also literally dissected so the

material and construction can be tested.

Among those tests...

Trialling the strength of seams and even the material

itself with a device to measure what pressure is

required to make it fail.

Above

we have a section of liner where the seams have been

tested, and a patch of denim where the material itself

has been stress-tested.

Next is what we like to call the 'belt and road' test.

It's literally an abrasion test with what looks like a

giant belt-sander that can be set to mimic road

conditions, and very precisely measure performance. Just

as a matter of interest, double-layered kevlar performed

relatively well in the demo we witnessed.

Armour

was a popular topic and the quality can vary enormously.

The researchers were too polite to say the word

'rubbish', but that clearly applied in one case that was

carrying fake CE standard markings.

One of the tools for armour evaluation is this, which drops a weight on the material and measure how much force is absorbed. The differences between dodgy and Level 2 absorption is enormous.

Something

we weren't expecting was this, a device that can be used

to measure breath-ability (temperature transfer) and the

effectiveness of claims to wick away moisture.

One section that wasn't open on the day was the rain room, though we were given a video demo. It's essentially a converted container that can set up a mist or light dousing to test any 'shower-proof ' claims. Fortunately it can be used with a test dummy rather than a real person in the riding gear!

MotoCAP is also working on a project to assess the longevity of riding clothing, or at least how quickly its protective qualities deteriorate. That report is yet to be completed, but is worth keeping an eye out for.

So are manufacturers taking any notice

of this work? The belief is the local brands are and there

is a sense they are modifying their range accordingly. One

model that springs to mind is a DriRider Climate EXO 4

jacket, which in its latest iteration has scored a

five-star safety rating.

There is a lot going on behind the scenes with this project and it's well worth spending a bit of time on the website.

We reckon you just have to take it into

account before you buy any riding gear.

-------------------------------------------------

Produced by AllMoto abn 61 400 694 722

Privacy: we do not collect cookies or any other data.

Archives

Contact